Masimo softFlow™

Masimo softFlow™

Nasal High Flow Therapy for Spontaneously Breathing Adult Patients in Hospital and Long-Term Care Facilities

- Respiratory support delivered through a soft nasal cannula interface

- Wide flow range from 10-60 L/min* in 0.5 L/min steps to permit flow rate to be tailored to the specific needs of the patient

- Ability to supplement oxygen with 0-60 L/min flow and up to 100% FiO2 from wall supply, oxygen cylinder, or concentrator

- Integrated flow driver provides flow without the need for wall air supply

- Warmed humidification of respiratory gas all the way to the patient’s nose to enhance therapy comfort and aid in mucous clearance1,2

- Condensate-free delivery of a consistent, high-velocity flow during inspiration and exhalation

- Auto-identification of type of nasal cannula and breathing circuit to improve and simplify workflow through automated configuration

- Bacterial/viral filter between device and patient, rather than between device and room air, to reduce risk of cross-contamination

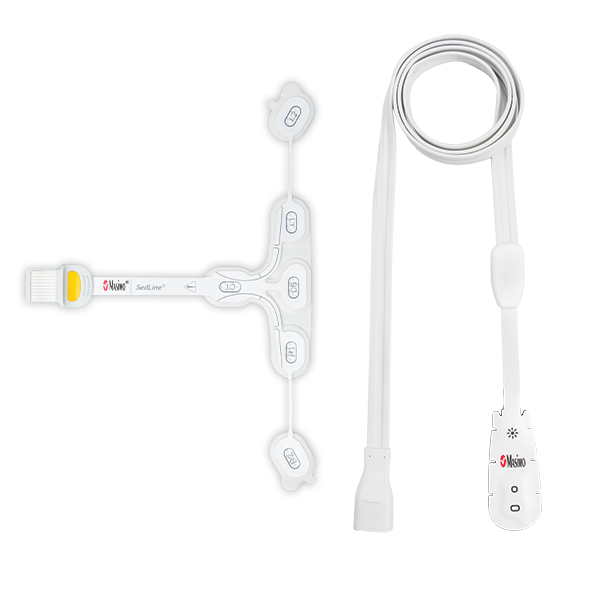

softFlow Accessories

softFlow Nasal Applicator

Available in Small, Standard, Standard-Plus, and Large sizes

Heater Wire in the Nasal Applicator

Unique one-piece design permits heater wire all the way to the nares to reduce condensation

softFlow Product Stand